As the world accelerates towards electric vehicles (EVs), the durability of key components, particularly batteries, takes on a new level of importance. The extreme temperatures present a formidable challenge, with direct implications for the efficiency and lifespan of EV batteries. To combat this, the spotlight falls on EV battery protection in extreme weather!

The lithium-ion battery, the heart of an EV, has its health closely intertwined with temperature regulation. The optimum temperature for battery performance lies between 15-45℃, with any deviation leading to degradation. Temperatures soaring above 60℃ can trigger thermal runaway, escalating the risk of fires or explosions, while frigid temperatures can curtail output, adversely impacting both range and power.

Acknowledging this, Battery Thermal Management Systems (BTMS) emerge as vital players in maintaining safe temperature thresholds. This article embarks on a journey into the complex realm of EV battery protection in extreme weather.

Understanding Thermal Sensitivity for EV Battery Protection in Extreme Weather

Extreme temperatures can degrade different components of a battery. Hence, let’s understand what it means to contribute towards EV battery protection in extreme weather.

High Temperatures

At extremely high temperatures, the battery may malfunction and degrade faster. The increased kinetic energy of particles at higher temperatures intensifies the rate of reactions, leading to a quicker breakdown of components and a reduction in overall battery performance.

Low Temperatures

At extremely low temperatures, the battery may cease to function temporarily. The electrochemistry becomes sluggish, and the available power is limited.

Optimal Temperature Ranges for Smooth Performance

The optimal temperature range of EV batteries lies between 20°C-40°C. Batteries maintain peak efficiency within this range, balancing energy storage and output optimally. In cold weather, the optimal range can drop by 10-12%, and the use of in-vehicle climate control could amplify range loss to 40%. In hot weather, the strain on the battery increases, which can hamper EV battery protection in extreme weather.

Notably, temperatures below 20°C slow down chemical reactions, reducing power and charging speed, while temperatures above 40°C hasten material degradation and elevate thermal risk. Consistently operating outside this optimal range shortens battery life and impacts performance.

Therefore, maintaining batteries within these temperatures is crucial for maximizing their lifespan and efficiency.

Challenges

Some challenges include:

- Vehicle Usage: High-speed driving or uphill driving can put more strain on the battery, generating more heat.

- Battery Charging/Discharging Rates: Fast charging or high-rate discharging can generate more heat within the battery.

- In-Vehicle Climate Control: Using the heater in highly cold weather or the air conditioner in very hot weather can increase the load on the battery, affecting its range.

Battery Thermal Management System Design for EV Battery Protection in Extreme Weather

Passive cooling and heating methods, such as natural convection and radiation, are used to provide EV battery protection in extreme weather. Active thermal control systems involve the use of external devices or systems to cool the battery, such as fans, heat sinks, and cooling fluids.

There are three main types of active thermal control systems:

1. Air Cooling: Active air cooling gets its air intake from an air conditioner, which includes an evaporator and a heater to control the air’s temperature. It is usually limited to 1kW of cooling and can be used to cool or heat the cabin.

2. Liquid Cooling: Liquid cooling uses a liquid coolant such as water, a refrigerant, or ethylene glycol to cool the battery. The liquid goes through tubes, cold plates, or other components that surround the cells and carry heat to another location, such as a radiator or a heat exchanger.

3. Phase Change-Based Cooling: Phase change materials (PCMs) absorb and release thermal energy during the process of melting and freezing.

Tradeoffs of Different Thermal Management Solutions

Each thermal management solution has its trade-offs in terms of efficiency, cost, complexity, and weight. For example, passive cooling delivers the lowest cooling performance, makes the smallest BTMS, is the lightest weight, has minimum points of failure, and uses no battery power. However, it is the least efficient approach for EV battery protection in extreme weather.

Advanced Materials Research for EV Battery Protection in Extreme Weather

Research in battery chemistry aims to widen the ideal temperature range for battery operation. For instance, a study reported the development of a wide-temperature lithium difluoro (oxalato) borate (LiDFOB), triethyl phosphate (TEP), and 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether (HFE) electrolyte, which enables stable cycling of lithium-metal batteries (LMBs) at high-voltages within a wide temperature range from -40 to 70 °C.

Development of Battery Components with Endurance

- Researchers are revolutionizing the lithium-ion battery by transforming it into an all-solid, or “solid-state,” version. This involves replacing the liquid electrolyte at the core of the battery with a thin, solid electrolyte that remains stable across a wide range of voltages and temperatures.

- In parallel development, synthetic inorganic fillers, such as silica (SiO2) and hexagonal boron nitride (h-BN), are being explored as potential fillers to enhance the insulation performance of high-voltage insulators.

Thermal Interface Materials Advancements in EV Battery Protection in Extreme Weather

Thermal Interface Materials (TIMs) provide a thermally conductive pathway, helping to regulate the temperature of the battery pack. However, TIMs are composite materials that are subject to degradation over the battery’s lifetime.

Emerging Solutions – Thermally Conductive Adhesives, Gap Fillers, Greases

Emerging solutions in the field of TIMs include:

- Thermally Conductive Adhesives: These adhesives enable the direct bonding of prismatic battery cells to aluminum cooling plates.

- Gap Fillers: They provide a thermally conductive pathway to exhaust excess heat and keep components within operating specifications.

Battery Pack Architecture Innovations for EV Battery Protection in Extreme Weather

Initially, battery packs were designed with simple structures, but as the need for better thermal management became apparent, more advanced designs were proposed.

Advanced Air Flow, Cooling Channels, Zoning in Pack Layouts

Advanced concepts for airflow, cooling channels, and zoning in pack layouts have been developed to improve thermal management, contributing to EV battery protection in extreme weather.

- Air Flow: U-type and Z-type parallel air-cooled structures are examples of forced air-cooled systems based on modified airflow channels with different airflow patterns.

- Zoning: This can influence the thermal performance of the battery pack, as the arrangement can affect the distribution of heat within the pack.

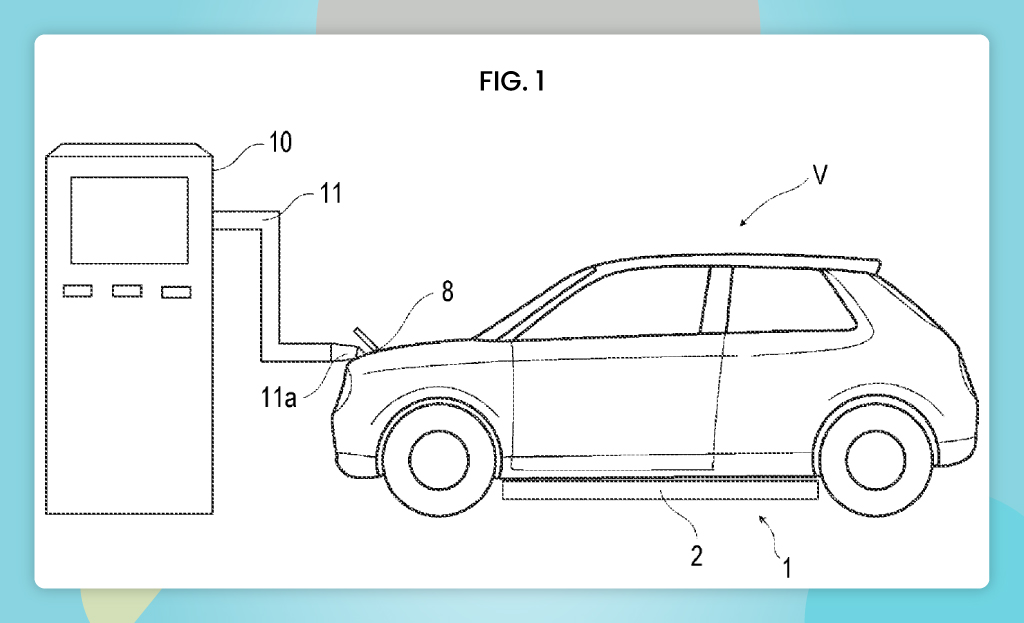

Patent Solutions

Here are some solutions that are patented for extreme temperatures:

- Sealing: Advanced sealing techniques are being developed to protect the battery from external elements.

- Thermal Insulation: Thermal insulation is crucial to maintain the battery’s temperature within an optimal range. The patent US9455478B2 describes an EV battery pack with a thermal assembly in thermally conductive contact with the upper cell surfaces of the array.

- Preventing Water Ingress: A battery pack for electric vehicles includes a special feature that prevents gas buildup. This design has a unique system that allows gases to escape while blocking water entry. It features a maze-like structure, enabling safe gas release and preventing water from getting into the battery. This ensures the battery pack remains secure and dry.

Final note

The performance and lifespan of these EV batteries are intricately tied to temperature regulation, making it a critical area of focus. Addressing this challenge requires a multi-faceted approach that combines advancements in materials, design, and BTMS.

This includes the development of innovative materials with improved thermal endurance, strategic design of battery pack structures, and advanced BTMS. As we continue to push the boundaries of technology, the future of EV battery protection in extreme weather looks promising and electrifying!